Solar Technology Laboratory

1| Laboratory of Photovoltaic Cells and Solar Collectors

Solar technology laboratory is dedicated for detailed characterization of laboratory scale and large scale photovoltaic cells and solar-thermal systems under sun-simulated illumination.

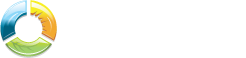

We are equipped with high quality solar simulators (AAA), quantum efficiency measurement system and UV-preconditioning system.

The large scale solar simulator from Eternal Sun is the first in Poland simulator providing constant light irradiation on 1.5×2 m area and one of few in Europe. It was awarded as a today’s top photovoltaic technology by PV magazine in 2015 and allows measurements on third generation of photovoltaic panels requiring long time illumination.

- Measurements of IV curves for PV panels with maximum dimensions of 1.5 x 2 m under constant illumination (AM0 or AM 1.5), at different angles between panel and a light source and determination of solar cells parameters: Isc, Imp, Voc, Vmp, FF, P max, efficiency, Rseries, Rshunt, standard test conditions (STC) data.

- Characterization of laboratory scale photovoltaic cells up to 16 x 16 cm2 under constant illumination (beam-down) and determination of solar cells parameters,

- Preconditioning test of solar panels under constant UV illumination (degradation tests),

- Characterization of spectral response (internal and external quantum efficiency) of photovoltaic cells in the range of 200-1100 nm dedicated single photovoltaic cells,

- Testing of solar-thermal systems: collectors under constant illumination and windy conditions.

2| Laboratory of Studies on Heat Pump Operating Parameters

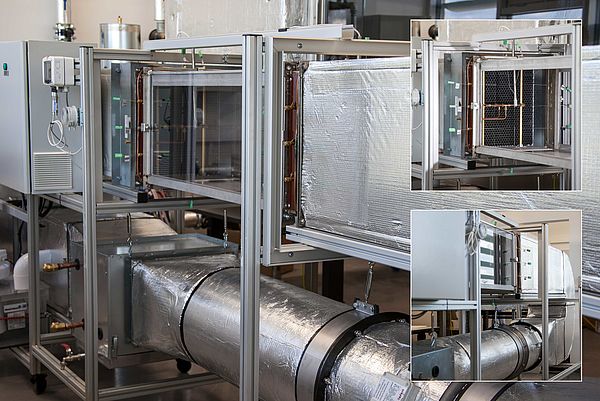

The facility enables comprehensive research of refrigeration and air conditioning systems and heat pumps in steady state conditions and in dynamic load conditions in a wide range of operation parameters. Due to its specificity the test bench is particularly suitable for variety of multiparametric optimization research tasks.

Detailed list of exemplary tasks available for realization at the experimental facility is given below:

- Research of coupled operation of a heat pump with a set of four photovoltaic – thermal cells in natural lighting conditions for a given upper heat source thermal load;

- Research of operation of four photovoltaic – thermal cells in natural lighting conditions with a cell-powered working fluid pump;

- Research of operation of liquid-liquid, air-liquid, liquid-air and air-air type heat pumps for various thermal loads up to 16 kW, for steady state conditions according to the PN-EN 14511 standard as well as dynamic load operating conditions;

- Research of operation of refrigeration and air conditioning devices for various thermal loads up to 16 kW, for steady state conditions according to the PN-EN 14511 standard as well as dynamic load operating conditions;

- Research of heat pumps, refrigeration and air conditioning devices with variable, controlled output, multiparametric device optimization, device automatics and control systems optimization;

- Research of refrigeration compressors;

- Research of heat exchangers;

The facility incorporates a precise, controlled heat load which enables achieving highly accurate and stable measurement parameters. The thermal load appliances feature a separate precise measurement system for thermal performance calculations.

3| Laboratory of Studies on Flow Structures in Heat Transfer and Electrostatic Precipitation Processes

The facility enables comprehensive testing of operation performance and basis of physical processes occurring during electrisation and removal of dust particles (fly ash) from the flow, particularly in distributed biomass energetic sources. Due to its specificity the test bench enables:

- performance measurement of a whole passage as well as individual electrodes and their particular regions;

- visualization of flow fields distributions in interelectrode and near-electrode surface areas

- measurement of current flow in particular areas of collecting electrodes.

The experimental facility enables measurements for a real-life gas composition (outflow gas simulators) and for actual-source-ashes (system of ash introduction into the flow). The test bench enables also for operation in real-life range (100 kV) of voltages supplied at the electrodes and the actual passage width dimensions (distance between electrodes ranging from 400 mm to 500 mm).

The experimental facility is suitable for testing of fly ash coming from combustion of biomass as well as special (e.g. waste) fuels. Closed gas circulation ensures safety for the workers and the laboratory room against harmful impact of fly ash and combustion gas simulators.